1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

As the manufacturing landscape continues to evolve, the demand for precision and quality in metal engraving machines has seen a remarkable rise. According to recent industry reports, the global metal engraving industry is projected to grow at a compound annual growth rate (CAGR) of 6.2% from 2023 to 2028, driven by advancements in technology and a growing need for customized solutions across various sectors, including aerospace, automotive, and jewelry design. This surge in demand is enabling manufacturers to refine their processes and enhance machine capabilities, making metal engraving machines more efficient and user-friendly than ever before.

In 2025, the market will likely be dominated by machines that incorporate innovative features such as laser technology, which allows for intricate designs and superior engraving quality on a variety of materials. With the increasing emphasis on automation and precision-engineered components, manufacturers are striving to deliver machines that not only meet but exceed stringent quality standards. As businesses seek to optimize production while maintaining high levels of customization and detail, investing in a top-quality metal engraving machine has never been more critical. This article explores the top five metal engraving machines that embody precision and quality, setting new benchmarks in the industry for the year ahead.

In 2025, the demand for precision and quality in metal engraving has reached new heights, driven by advancements in technology and the expanding needs of various industries. A recent industry report indicated that the global metal engraving machine market is projected to grow at a CAGR of 6.5% over the next five years, reflecting the rising interest in customized and high-quality engraving solutions. This growth is largely attributed to the increasing applications across sectors such as automotive, aerospace, and jewelry manufacturing, where intricate designs and precise markings are crucial.

As manufacturers seek to enhance their production capabilities, several key features are emerging as essential in modern metal engraving machines. High-speed processing, superior laser technology, and user-friendly software interfaces are now expected as standard components. Furthermore, advancements in robotics and automation have significantly improved engraving accuracy, resulting in less material waste and optimized production timelines. According to a survey conducted by the International Society of Engraving Professionals, over 75% of respondents highlighted the importance of precision in their operations, demonstrating that investing in quality machines is not just beneficial but necessary for maintaining competitive 优势 in the evolving market landscape.

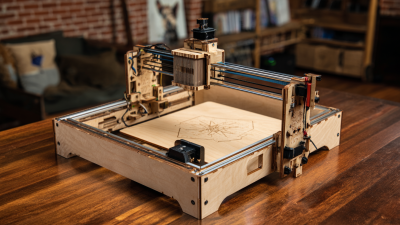

Precision in metal engraving is paramount to achieving high-quality results that meet industry standards. The intricate nature of metal products, whether for artistic purposes or functional components, demands tools that can consistently deliver accuracy. Engraving machines that prioritize precision are essential for professionals in various sectors, including manufacturing, jewelry design, and custom hardware. A capable engraving machine must be able to handle detailed designs, ensuring that every stroke contributes to a flawless final product.

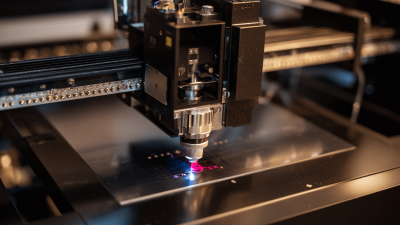

Moreover, the techniques utilized in metal engraving have evolved significantly, reflecting advancements in technology and materials. Laser engraving, for instance, has become a favored method due to its ability to produce clean, precise lines with minimal material disruption. This technique not only enhances efficiency but also opens new channels for creativity, allowing artists and designers to explore complex patterns with ease.

As industry standards continue to rise, the importance of selecting the right engraving machine, equipped with the latest technology, becomes even more critical to maintaining high-quality outputs and meeting client expectations.

When selecting a metal engraving machine, precision and quality are paramount. One of the key features to consider is the machine’s engraving resolution, often measured in dots per inch (DPI). According to a report by MarketsandMarkets, the demand for high-resolution engraving solutions is projected to grow at a CAGR of 5.4% from 2022 to 2027. Machines offering resolutions of 1200 DPI and above allow for intricate designs and detailed artwork, catering to markets requiring high-quality finishes.

Another critical aspect is the type of engraving technology employed. Laser engraving, known for its versatility and precision, is favored in industrial applications. A study published by Research and Markets highlights that laser engraving systems account for nearly 40% of the market share in metal engraving technologies. Furthermore, the ability to work with various materials—from aluminum to stainless steel—enhances a machine's utility, making it essential to choose models that support multiple substrates. Additionally, consider the machine's software compatibility, as advanced applications for design and control can drastically improve operational efficiency and output quality, facilitating integration into existing manufacturing environments.

| Model | Engraving Area (mm) | Laser Power (W) | Max Engraving Speed (mm/s) | Weight (kg) | Price Range (USD) |

|---|---|---|---|---|---|

| Model A | 300 x 200 | 50 | 600 | 25 | 1,200 - 1,500 |

| Model B | 400 x 300 | 80 | 800 | 35 | 1,500 - 2,000 |

| Model C | 500 x 400 | 100 | 700 | 40 | 2,000 - 2,500 |

| Model D | 600 x 500 | 120 | 900 | 45 | 2,500 - 3,000 |

| Model E | 700 x 600 | 150 | 1,000 | 60 | 3,000 - 4,000 |

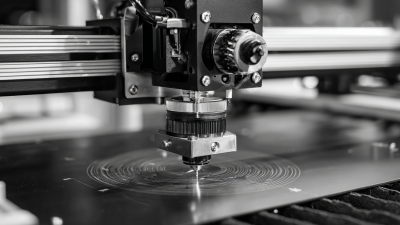

When evaluating the top metal engraving machines of 2025, performance metrics play a crucial role in determining their effectiveness and reliability. Users in industries such as manufacturing, jewelry design, and personalized engraving seek machines that combine precision with durability. Key performance indicators include engraving speed, accuracy, and the versatility of materials that can be processed. Machines that exhibit high-resolution capabilities are favored for their ability to deliver intricate designs and clean finishes. Additionally, the adjustability of engraving depth ensures that various substrates can be effectively marked without compromising quality.

Moreover, ease of use and integration with design software are vital for enhancing productivity. Machines that offer intuitive interfaces and compatibility with advanced design programs enable users to streamline their workflow. Furthermore, the durability of the engraving components is essential for ongoing operation, minimizing downtime due to maintenance or repairs. The top machines distinguish themselves not just through their raw performance but also by how seamlessly they fit into the modern production environment, allowing for quick setup and efficient operation. This comprehensive analysis highlights the importance of investing in technology that not only meets today's standards but is also adaptable for future advancements in metal engraving.

When selecting a metal engraving machine, customer reviews serve as a valuable resource for potential buyers seeking both precision and quality. Users often share their experiences regarding functionality, ease of use, and durability, shedding light on the machines that truly stand out in the engraving industry. Positive feedback frequently highlights the machines' ability to produce intricate designs with minimal effort, ensuring that even novice users can achieve professional results. Conversely, critical reviews often identify issues related to reliability or design flaws, emphasizing the importance of thorough research before making a purchase.

Tips for prospective buyers include investigating the warranty and customer support offered by the manufacturers. A robust warranty along with responsive customer service can save time and money in the long run. Additionally, looking for detailed user guides and online tutorials can enhance your engraving experience significantly. Engaging with user communities through forums or social media groups can provide insights and recommendations from experienced engravers, making it easier to identify reliable machines.

Ultimately, high customer satisfaction typically correlates with the quality of the engraving machine. Machines that receive consistent praise for their precision and ease of use tend to be the best investments. Therefore, taking the time to read through reviews and consider user feedback will greatly improve the chances of finding the right machine that meets specific engraving needs.