1101 W. Sanilac Rd. Caro, MI 48723

989.673.6690

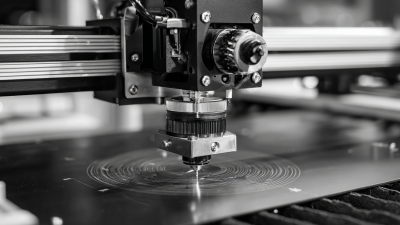

When it comes to engraving metal, having the right tools is essential for achieving high-quality results. A laser engraver for metal can significantly enhance your productivity and precision, making it a favored choice among both hobbyists and professionals alike. However, with a myriad of options available on the market, selecting the most suitable laser engraver can be daunting. This comprehensive guide aims to equip you with the knowledge needed to make an informed decision, ensuring that you choose a device that best meets your specific requirements.

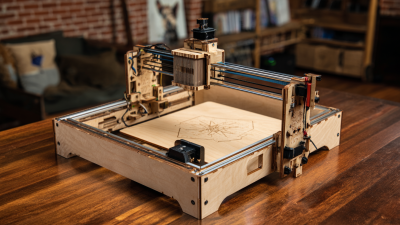

In this guide, we will explore various factors to consider when choosing a laser engraver for metal, including power options, engraving speed, and material compatibility. By understanding these key elements, you will be better positioned to evaluate different models and features. Whether you are looking to start a small engraving business or to take on creative projects at home, this guide will serve as your roadmap to successfully navigate the world of metal engraving, unlocking your potential for endless creative expression.

When selecting a laser engraver for metal, it's essential to understand the different types available on the market. The main types include fiber lasers, CO2 lasers, and DPSS (Diode-Pumped Solid-State) lasers. Fiber lasers are particularly advantageous for engraving metals like stainless steel and aluminum, as they offer high precision and speed. Their solid-state technology allows for exceptional energy efficiency and minimal maintenance, making them a preferred choice for many industrial applications.

CO2 lasers are often used for various materials, including wood and plastics, but they can also engrave coated metals. While they may not be as effective as fiber lasers on bare metals, their versatility in handling different materials makes them suitable for multi-use environments. On the other hand, DPSS lasers provide a good balance for both engraving and cutting metals, though they may not be as commonly utilized as the other two types. Understanding these distinctions is crucial for making an informed decision based on the specific applications, materials, and desired outcomes of your engraving projects.

When selecting a laser engraver for metal, several key features should be considered to ensure optimal performance and satisfaction. One of the primary aspects is the type of laser technology used, with CO2 and fiber lasers being the most common for metal engraving. Fiber lasers are particularly effective for engraving on a wide variety of metals and offer faster processing speeds. Additionally, consider the power output of the engraver, as higher wattage typically translates to deeper and more precise engravings.

Another important feature is the engraver's bed size, which determines the maximum dimensions of the materials you can work with. A larger working area allows for greater flexibility in projects, especially when dealing with larger metal pieces. Furthermore, look for machines that offer adjustable speed and frequency settings, as these can greatly influence the quality of the engravings depending on the type of metal being used. Lastly, ensure the engraver has a user-friendly interface and robust software compatibility to simplify the design and production process.

When selecting a laser engraver for metal, evaluating its engraving capacity and material compatibility is crucial. The engraving capacity refers to the machine’s ability to create detailed designs on metal surfaces. This includes factors such as the wattage of the laser, which plays a significant role in determining depth and precision. A higher wattage can cut through thicker metals and produce finer details, making it essential to choose a machine that aligns with your specific engraving needs. Additionally, consider the type of laser used, such as fiber or CO2 lasers, as each type can affect performance on different metals.

Material compatibility is another key aspect to evaluate. Not all laser engravers are suitable for every type of metal. Common metals like aluminum, stainless steel, and brass may require different settings to achieve optimal results. Ensure the engraver you’re considering is capable of handling the metals you intend to work with and has adjustable settings to accommodate various thicknesses and compositions. Understanding these factors not only enhances the quality of your engravings but also prolongs the lifespan of your equipment, ensuring better investment in the long run.

| Feature | Description | Recommended Capacity |

|---|---|---|

| Laser Type | Fiber lasers are best for metal engraving due to their efficiency and power. | 20-50W for high precision |

| Engraving Speed | Higher speeds can increase productivity, but may affect detail quality. | 200-800 mm/s |

| Material Compatibility | Engravers should support a variety of metals, including stainless steel, aluminum, and brass. | Supports multiple types of metals |

| Cooling System | An efficient cooling system is necessary to prevent overheating during long operations. | Water cooling preferred |

| Software Compatibility | Engraving software should be user-friendly and support various file formats. | Compatible with popular software (e.g., AutoCAD, CorelDRAW) |

| Price Range | Consider your budget while ensuring you get a reliable machine. | $2000 - $5000 for quality models |

When choosing a laser engraver for metal, understanding the distinction between budget options and professional-grade lasers is crucial for making an informed decision. Budget lasers, typically priced between $200 and $1,000, offer basic engraving capabilities. They are ideal for hobbyists or small businesses that only require occasional engraving on softer metals like aluminum or brass. However, they often struggle with thicker materials and may not provide the precision or speed needed for more complex designs. Industry reports indicate that while budget machines can perform adequately for light use, their longevity and result consistency may be lower when compared to more robust options.

On the other hand, professional-grade lasers, priced from $2,000 to upwards of $10,000, are engineered to handle a wide range of metals, including stainless steel and titanium. These machines feature advanced features such as higher wattage, which allows for faster engraving speeds and deeper penetration into materials. According to a recent market analysis, professional-grade systems can yield returns on investment significantly faster due to their efficiency and the quality of work produced. They not only offer enhanced durability but also come equipped with support services and warranties that appeal to commercial users. For businesses looking to scale their production or for artists aiming for high-quality outputs, investing in a professional laser engraver can make a substantial difference in operational capabilities and overall product quality.

Maintaining your laser engraver is essential for ensuring its longevity and optimal performance. Regular maintenance not only extends the lifespan of the equipment but also enhances the quality of engraving. According to a report from the Laser Institute of America, proper maintenance can reduce downtime by up to 30%, which is crucial for businesses relying on high-output production.

Simple practices such as regular cleaning of lenses, checking alignment, and monitoring cooling systems can significantly impact the efficiency and effectiveness of your engraver.

Support and service also play a vital role in keeping your laser engraver running smoothly.

Research indicates that manufacturers offering comprehensive support packages can improve customer satisfaction and reduce operational costs by providing timely assistance and replacement parts. A study from the International Organization for Standardization emphasizes that having a reliable support system can help identify and resolve potential issues before they escalate, ensuring that users can continue their operations without unnecessary interruptions.

Investing in a laser engraver with a strong support network is therefore a strategic move for businesses aiming for sustained productivity.